Parts List:

ComposiStone (2lbs), Hot glue, Spray adhesive, PureCast605, Elmer’s Glue, Used ComposiMold, ProtoCast85R, Water, Toy Robot, Silicone, Cardboard Box’s, Paint, Colored tissue Paper, Cups, Wires, Delight Paper Clay, Plastic bags/ trash bags, Breadboard, Recordable Card, Controller, Ferrules, Electric Switch, Receiver, Electrical tape, Rubber gloves, Packing tape, LED Lights, Clay, Bubble Buster, Mold Release, Arduino, Stir Sticks, Plates/tray for mixing paint.

The Amount of ComposiMold used for each part of the robot is as follows:

• Arms..3.7Lbs each• Head.. 1Lb

• Legs ….10.4Lbs

• Body…9.3Lbs

Equipment:

Microwave, Hot glue gun, Laptop, Pliers, Scissors, Scale, USB to mini USB, Wire strippers.

Outline of the Video:

The video starts with creating the mold box using a cardboard box, plastic bag, and spray adhesive followed by preparing the robots legs by anchoring them down with clay, spraying them with bubble buster and mold release.

The ComposiMold is melted down in a microwave and poured over the prepped Robot legs. After the mold is poured; the ComposiMold is left to cool to solidify.

The legs are removed by cutting and flexing the rubbery mold. The mold is taped up in preparation for the casting material.

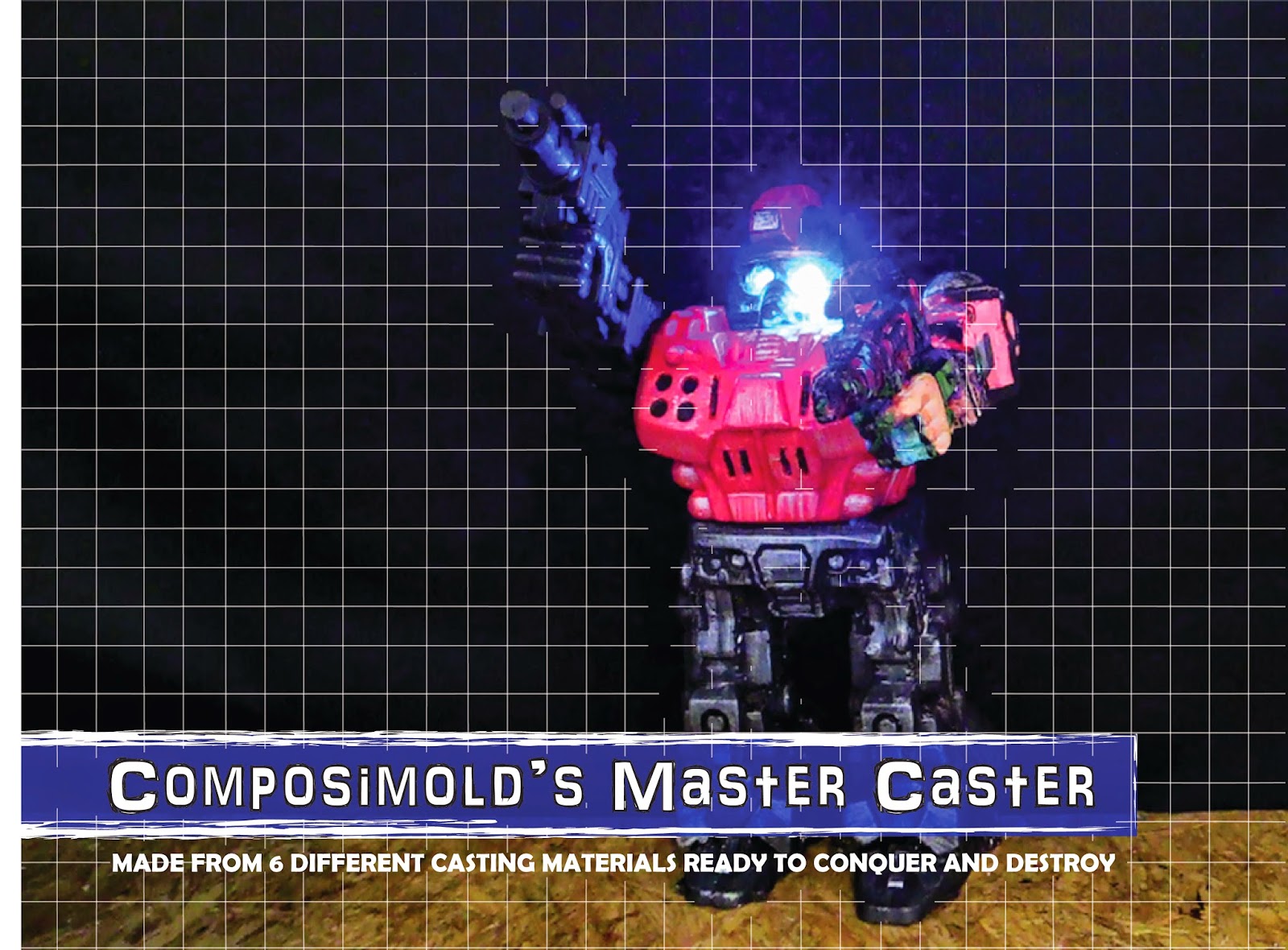

Then the various types of casting materials used for each of the robots five body parts are demonstrated. The robots legs are first up; ComposiStone (Plaster like material) is mixed and poured into the mold. Next I explain how the robots head was casted with PureCast 605 and how I was able to embed LED lights in the material. Then I explain how the body was casted using ProtoCast85R. I will then go over how to cast one of the arms using decoupage and delight modeling compound. The other arm is casted in silicone; were I start by showing how to mix the material followed by pouring and later removing the piece from the mold. Next we paint the robot, wire the Arduino, write the code, and start playing with the remote control robot!

For More Information visit:

www.ComposiMold.com

There is a bunch of mold growing in our basement. I think the sprinklers have been putting water down there. I'll have to adjust them so they don't. http://www.moldstoppersremediation.com

ReplyDeleteIt’s a classic awesome post, I am lucky that I visited this blog site, it gives supportive ideas. safety equipment

ReplyDeleteThis blog post is really great; the quality information of this post is genuinely incredible. www.moldcareer.com

ReplyDelete