The following speach was giving at the Maine Association of Manufacturers when ComposiMold was nominated as the Innovator of the Year.

Experiment. It’s not just a bubble gum flavor. Business is about

experimenting. Nothing? Get it? Spearmint flavored bubble gum…experiment? That

failed. You rarely know what’s going to

be successful until you try it. Experimenting is key. Try this, try that,

double down on what works, move past what doesn’t. Every chance you get, you

need to experiment with ideas with strategies and ideas.

So where do you start? You start with an idea. And here’s a

secret for coming up with ideas. Just keep asking “wouldn’t it be great if…”and

answer that. In 30 minutes you can come up with 100’s of ideas. In a month you’ll come up with 100’s of good

ideas. I have a notebook, now a computer document, filled with ideas ranging

from launching a rocket off the side of a mountain to reduce the fuel needed

get moving to an automobile that could be customized using different outer

shells and body components. But of course, those ideas aren’t reality. I don’t

even know if they’re any good. It’s only through learning and experimenting that

we can see what ideas are good, bad, or somewhere in between.

ComposiMold was my experiment because I needed a tool to

help me make my ideas into real parts and pieces. I started with one product in

the ComposiMold business: a reusable heat and pour mold making material. And it

was a one page business plan experiment summarized in a statement “I like it,

let’s see if others will like it too.” I started with a little cooker in my

basement. After the first successes, I doubled my production by going to 2

cookers. After the 3rd cooker, it was time to get out of the house

and scale-up to real production levels. And thus the trek continued. It’s been

10 years now and I’m still learning and we’re still experimenting.

And with

ComposiMold you can make awesome stuff into real materials. You can make ideas,

change ideas, re-make shapes, parts, pieces, and more. And see what happens.

You can make awesome. I know because I get to see what our customers make every

week.

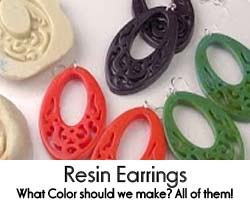

Robot parts, chocolate birthday shapes, Action Figures,

jewelry, reusable molds for vacuum forming inserts. Whole businesses based around a mold making

and casting material where you don’t have to keep on buying the mold making

material. In the molding industry, this is a paradigm shift. Custom mold making

where you can customize your molds, or as an admirer once said once “This is a

3D printer for the rest of us.” And you’re not limited in material options.

And it is through experimenting, you can make awesome. ComposiMold

is your tool for mold making and casting. You can compare it to a hammer or saw

for carpentry. Or a paint brush for painting. When you want to duplicate

something, ComposiMold products are there.

But to be awesome takes experimenting. It takes learning.

It takes skill. You don’t learn calculus before you know algebra. You can’t

paint the Mona Lisa before you learn to draw. Start simple and grow. And when

it comes to tools for mold making, you can’t beat the convenience and ease of

ComposiMold’s mold making materials.

The ComposiMold experiment started with ComposiMold. This

product came out of me making a lot of mistakes. Seems to be the Story of my life.

The basics is this: I like crashing model airplanes for a hobby. And when you

crash a lot you have to build a lot. And at the time I was building a model

airplane that required a whole bunch of spars for the wings. And I didn’t want

to make them all by hand. So mold making was a great idea, but in reality it

was hard to do, the options were smelly, toxic, and hard to use. There was no tools, just materials that you

bought. At first my shapes floated, I had bubbles in the molds, I had holes in

the molds. So there’s that idea question from the beginning “wouldn’t it be

great if…” I could learn how to make molds without wasting all this money. That

used a non-toxic molding material so I could use it in my kitchen without

worry, and wouldn’t it be great if I was able to make dozens of molds with the

same mold making material…ya, that would be great.

And since you can’t get a hit unless you swing the bat, I

put the product out there to see what happens. First selling on Ebay, then a

website, then resellers. The first reseller was the University of Montana. I

also had great advice from the people at Artist & Craftsman. I had no idea

what to do! But we got it done! And then we added distributors and

international sales. We now have over 100 different products based around our

two main mold making materials: ComposiMold, a heat and pour molding material

and ImPRESSive Putty and heat and press, press…get it. Yes, the name is

obnoxious, but the product really is an impressive tool. These molding

materials are your tools for mold making and casting anything from plastics, composites,

to chocolate, clay, soap, candles, and so much more. You can do it with

ComposiMold. And you can start simple and go to as complex as you want. All

with the same mold making materials.

We are now available in over 600 stores and online, through

Europe, North America, and Australia and every week we are continuing to look

at new products and business experiments

We have casting materials including ComposiCast Resins,

colorants, and ComposiStone, We have multiple instructional books, ebooks, over

200 video tutorials, and we keep on experimenting. Our newest product experiment

is an eco friendly biodegradable soft bait lure making kit that lets anglers

make the soft bait lures like they make their own flies. We put out a simple

version of this kit last year just to see what happens, and it’s been very

popular. So we’re making a better version of this kit for this year.

I can’t wait to see what happens next on this amazing, no

sorry, ImPRESSive Bubble Gum Flavored Experiment. Thank you.

For More Information Visit: