Casting with Plaster of Paris

|

| Seashell in Plaster of Paris |

Plaster of Paris is low cost, easy to use, and makes good

castings. Plaster of Paris comes as an easy-to-mix formula that mixes with water and

dries to a dense, durable, and smooth and bubble free finish. Plaster of Paris is a great material to use for

basic castings and molds and art projects because it is simple to mix and use.

The Plaster of Paris sets in a few minutes, although it takes an hour before it

is ready to be removed from the mold. It takes 24-48 hours to fully cure. Using Plaster of Paris is easy, but there are

procedures to follow that will make you successful in your plaster castings.

|

| Plaster Casting of Frogs |

Plaster of Paris is not a

plastic. It is a hard white substance made by the addition of water to

powdered and partly dehydrated gypsum. It is hard like a cement or

concrete but white and not as strong. So don’t use plaster for very thin

castings. Basic shapes or designs that have a solid backing to them will be

more successful. If you need some flexibility or stiffness in the final

castings, then move to a plastic.

|

| Creepy Plaster Casting of a Dolls Head |

Materials you will need:

·

Plaster of Paris powder. For ComposiMold or ImPRESSive Putty

Molds, please use our ComposiMold plaster that has been formulated to cure to a

strong solid casting in these molds. By creating cure more quickly, the water

in the plaster does not react with the ComposiMold or ImPRESSive Putty to give

strong, hard plaster castings. You can also purchase a powder additive to add

into any plaster of paris to obtain a similar affect.

·

Water: Use cold water to cure slower and give you more control

over the reaction and give more time to fill the molds.

·

Mixing container that is large enough to hold to water and

plaster. Plastic containers are nice because you can deform them afterwards to

break away the hard plaster and re-use the container.

·

Measuring cup or any cup that can be used to measure out 3 parts

of plaster powder to 1 part water.

Make your Plaster Castings

The

ideal ratio for a Plaster of Paris mixture is 3 parts Plaster of Paris powder

to 1 part water. Measure out the water and pour it into your mixing container.

Some recipes suggest 2 parts plaster to water, but this will create a much

weaker plaster casting. The thicker you can be while still being able to pour

the better. Start with a 3 to 1 ratio and if necessary add small amounts of

water to make it easier to pour.

Break

any clumps of plaster up with a spoon. If you use your hands to mix, be sure to

wear gloves.

When

mixing the water and plaster, you should mix the powder into the water. Pour the plaster powder into the water

spreading it out over the surface of the water. After it is poured all poured

in, tap the sides of the mixing container and let the plaster powder fill with

water to reduce bubble formation. The plaster powder will sink into the water.

When you are finished adding the plaster, it will be slightly above the surface

of the water and not easily absorbed by the water.

Gently

stir the plaster and water to form a nice slurry similar to a thick pancake

mix. Gentle stirring of the plaster will

reduce the chance of bubbles being mixed into the mixture.

Pour

the plaster into your molds. If you want to learn how to make your own molds,

check out our mold making videos and get your free mold making e-book.

A couple other tips for plaster casting:

Do not pour any extra plaster down your drain. It can harden

and destroy your plumbing. You can dilute the plaster so it does not create a

hard plaster or let it harden and throw it away.

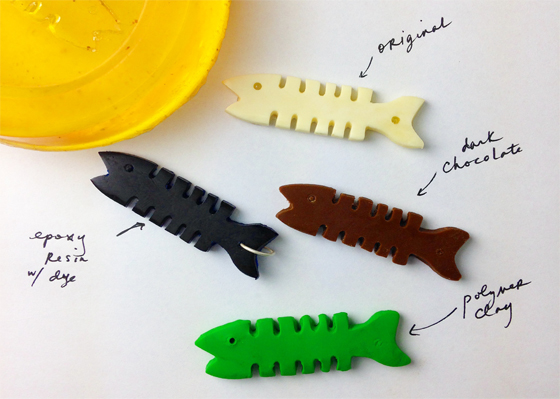

To make colored plaster, you can add colorants to the plaster mix while it is still in liquid/paste form. Remember that you will be adding color to white, so you will need more colorant to make darker colors. Any types of paint will work.

To paint the plaster casting after it has cured, use a layer of gesso or primer first to seal the plaster, and then you can paint the plaster any way you want.

Video of Plaster Casting of a Duck Decoy