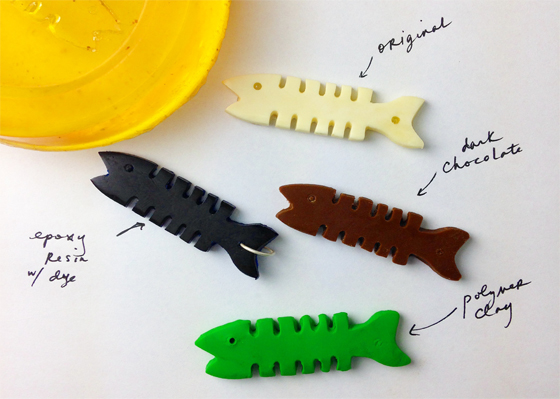

Here are some quick tips for the variety of casting materials you can use in a ComposiMold mold:

|

| EPOXIES: Epoxy Resins, Putty, or Clay Epoxies work well for pieces up to 8 cubic inches. For larger castings of 8+ cubic inches, choose epoxies with longer cure times of 24+ hours. Experiment with freezing the mold prior to pouring epoxy resins that create a lot of heat during curing. Epoxy resins that require an added heat source for curing are not recommended. Try our jewelry grade, crystal clear, Clear Casting Plastic for castings up to 6 cubic inches. Chill the mold for castings up to 20 cubic inches. URETHANE OR POLYURETHANE: Choose a urethane with a longer cure time. These create less heat as they cure. You can also experiment with freezing the mold prior to pouring higher temperature urethane resins. Be sure to use talc powder/baby powder as your mold release before each casting made. SILICONE: Silicones work great in ComposiMold molds. Make castings with both platinum or tin cured silicone rubbers. PLASTER/CONCRETE: Mix plaster and water together in a 72 parts plaster to 28 parts water, by weight, or to a toothpaste-like consistency. Traditional plasters cure well but leave a slight soft layer on the outside of the casting. To avoid this, apply a layer of Plaster Release to the mold before pouring casts. Fast curing masonry cements work great and cure extremely strong. Follow instructions for mixing ratios. Try our ComposiStone formulation! It’s smooth like plaster but hard as concrete. It works very well in a ComposiMold mold. SOAPS: Shea Butter and Glycerine Soap make great soaps! Chill the mold prior to pouring any higher temperature soaps (above 140ºF). WAXES: (for candle molds or encaustic casting) Soy, Paraffin, Beeswax, and Melted Crayons work really well. Chill the mold first for higher temperature waxes (above 140ºF). Try our all natural Soy Candle Wax for candle making and beautiful wax castings. Cools to a white, creamy finish! CLAYS: Use any type of polymer clay, modeling clay, putty, or real clay for push molding in a ComposiMold. Do not use clay in a slurry form or the water will degrade the mold. CHOCOLATE: Pour or pipe many types of melted chocolate into your mold. Lightly tap or vibrate the mold to release air bubbles in the chocolate. No mold release is necessary for chocolates. FONDANT: Press softened fondant into your mold with your hands or a rolling pin and remove immediately. No mold release is necessary for fondant. When casting edible treats, you can also use: no-rise cookie dough recipes, gummies, gum paste, ice, butter, and more! ...AND MANY MORE: For your art, craft, hobby, and hardware projects, you can also try: adding fillers and dyes to casting materials, ComposiMold itself as a rubber casting material, Modeling Compounds, Polyester Resin, Paper Mache and many more! |

|  |  |

Do you have a question about using a specific casting material that was not answered here? Email or call anytime!

|

Please share this video and tell everyone you know about ComposiMold! Plus subscribe to see the next amazing blog post from ComposiMold!

For More Information Visit: